Our Range

Access Floors For Every Project

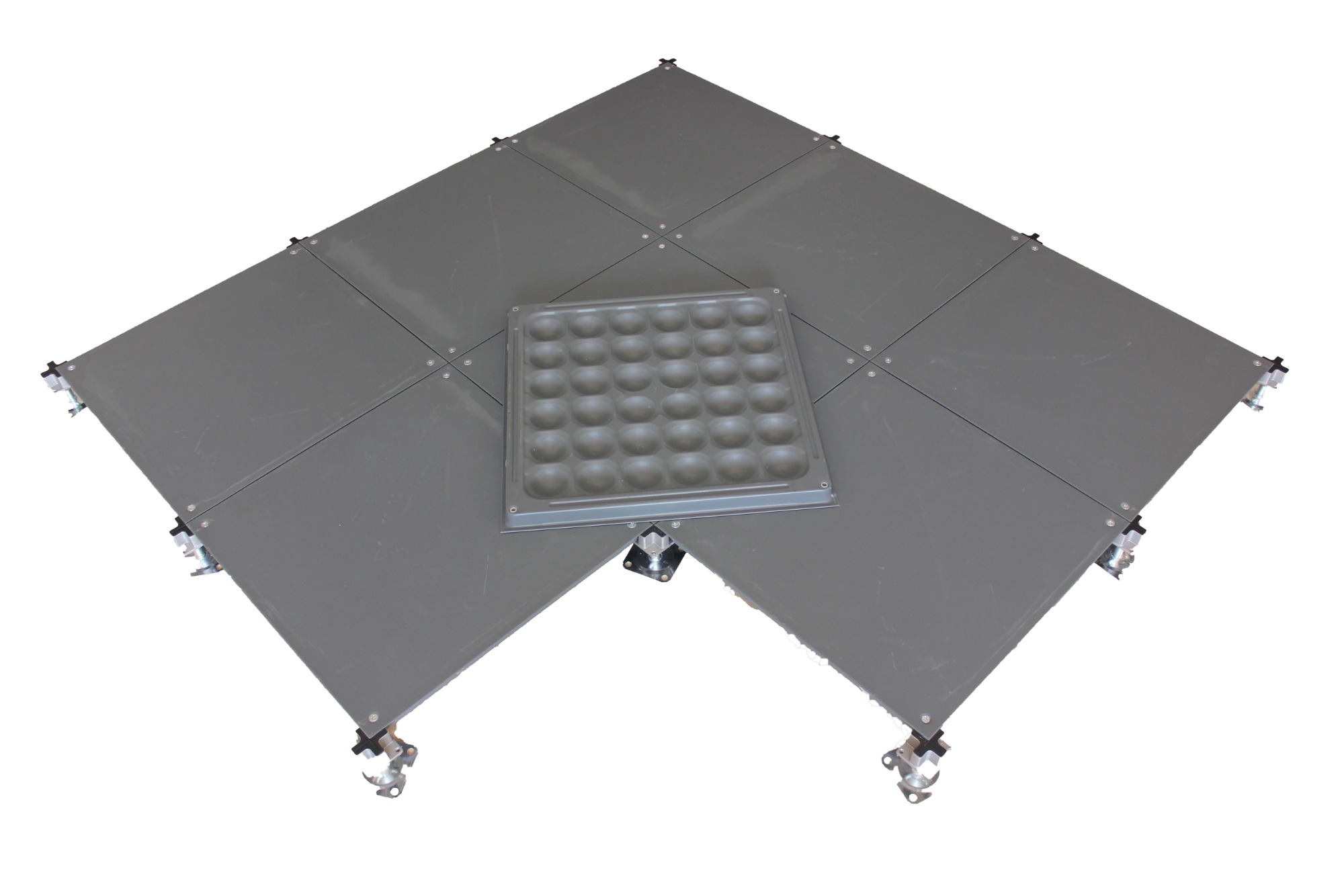

Cementitious Steel Anti-static Data Room Raised Access Floor

Finish: PVC/ HPL Tile

This panel provides a high-loading, anti-static working surface. Ideal for data rooms, wiring boxes and outlets can be installed on the platform and the pedestal height can be adjusted to suit your requirements.

| Model | Int. | Size (mm) |

Fire Performance |

Concentrated Load (KG) | Impact Load (N) | Ultimate Load (N) |

Uniform Load (N/M²) |

| LP-1014 | FS700 | 600x600x35 | A | ≥ 301 | ≥ 445 | ≥ 8850 | ≥ 12500 |

| LP-1015 | FS800 | 600x600x35 | A | ≥ 363 | ≥ 563 | ≥ 10680 | ≥ 16100 |

| LP-1016 | FS1000 | 600x600x35 | A | ≥ 453 | ≥ 670 | ≥ 13350 | ≥ 23000 |

| LP-1017 | FS1250 | 600x600x35 | A | ≥ 567 | ≥ 780 | ≥ 16680 | ≥ 33000 |

| LP-1018 | FS1500 | 600x600x35 | A | ≥ 680 | ≥ 890 | ≥ 26690 | ≥ 43000 |

| LP-1019 | FS2000 | 600x600x35 | A | ≥ 906 | ≥ 1005 | ≥ 31130 | ≥ 58000 |

Cementitious Steel Anti-Static Raised Floor

Finish: Ceramic

This panel is widely applies to high-grade rooms where there is a requirement for high load capacity and long service life, such as banks, telecommunication rooms, monitoring rooms and office buildings. The ceramic finish provides an attractive visual appearance.

Available in 600x600x40 (mm) & 600x600x45 (mm)

| Model | Int. | Size (mm) |

Concentrated Load (KG) | Impact Load (N) | Ultimate Load (N) |

Uniform Load (N/M²) |

| LP-2010 | FS662 | 600×600 | ≥ 301 | ≥ 445 | ≥ 8850 | ≥ 12500 |

| LP-2011 | FS800 | 600×600 | ≥ 363 | ≥ 563 | ≥ 10680 | ≥ 16100 |

| LP-2012 | FS1000 | 600×600 | ≥ 453 | ≥ 670 | ≥ 13350 | ≥ 23000 |

| LP-2013 | FS1250 | 600×600 | ≥ 567 | ≥ 780 | ≥ 16680 | ≥ 33000 |

Steel Network Floor - Standard

Finish: Standard

This panel is manufactured with a full steel structure, high dimensional precision and a strong loading capacity. These panels are ideal for office buildings, computer rooms and environments with plenty of cabling/ wiring.

| Model | Int. | Size (mm) |

Concentrated Load (KG) | Impact Load (N) | Ultimate Load (N) |

Uniform Load (N/M²) |

| LP-2019 | FS440 | 600x600x35 | ≥ 200 | ≥ 295 | ≥ 5880 | ≥ 9720 |

| LP-2020 | FS662 | 600x600x35 | ≥ 301 | ≥ 445 | ≥ 8850 | ≥ 12500 |

| LP-2021 | FS800 | 600x600x35 | ≥ 363 | ≥ 536 | ≥ 10680 | ≥ 16100 |

| LP-2022 | FS1000 | 600x600x35 | ≥ 453 | ≥ 670 | ≥ 13350 | ≥ 23000 |

| LP-2023 | FS1250 | 600x600x35 | ≥ 567 | ≥ 780 | ≥ 16680 | ≥ 33000 |

| LP-2024 | FS1500 | 600x600x35 | ≥ 680 | ≥ 1005 | ≥ 19980 | ≥ 34500 |

| LP-2019 | FS440 | 500x500x28 | ≥ 200 | ≥ 295 | ≥ 5880 | ≥ 9720 |

| LP-2020 | FS662 | 500x500x28 | ≥ 301 | ≥ 445 | ≥ 8850 | ≥ 12500 |

| LP-2021 | FS800 | 500x500x28 | ≥ 363 | ≥ 536 | ≥ 10680 | ≥ 16100 |

Steel Network Floor - Freestyle Combination Trunking

Finish: Freestyle Combination Trunking

On the base of a standard steel network floor, the trunk can be located in any place between panels which allows cabling to run through this section instead of beneath the floor in the plenum. Standard or deepened trunking is available as required, allowing the wiring to be more flexible e.g separating strong and weak currents. The trunks are level with the panels which saves space and provides easier maintenance.

| Model | Int. | Size (mm) |

Concentrated Load (KG) | Impact Load (N) | Ultimate Load (N) |

Uniform Load (N/M²) |

| LP-2019 | FS440 | 600x600x35 | ≥ 200 | ≥ 295 | ≥ 5880 | ≥ 9720 |

| LP-2020 | FS662 | 600x600x35 | ≥ 301 | ≥ 445 | ≥ 8850 | ≥ 12500 |

| LP-2021 | FS800 | 600x600x35 | ≥ 363 | ≥ 536 | ≥ 10680 | ≥ 16100 |

| LP-2022 | FS1000 | 600x600x35 | ≥ 453 | ≥ 670 | ≥ 13350 | ≥ 23000 |

| LP-2023 | FS1250 | 600x600x35 | ≥ 567 | ≥ 780 | ≥ 16680 | ≥ 33000 |

| LP-2024 | FS1500 | 600x600x35 | ≥ 680 | ≥ 1005 | ≥ 19980 | ≥ 34500 |

| LP-2019 | FS440 | 500x500x28 | ≥ 200 | ≥ 295 | ≥ 5880 | ≥ 9720 |

| LP-2020 | FS662 | 500x500x28 | ≥ 301 | ≥ 445 | ≥ 8850 | ≥ 12500 |

| LP-2021 | FS800 | 500x500x28 | ≥ 363 | ≥ 536 | ≥ 10680 | ≥ 16100 |

Steel Network Floor - Conjoined Trunking

Finish: Conjoined Trunking

| Model | Int. | Size (mm) |

Concentrated Load (KG) | Impact Load (N) | Ultimate Load (N) |

Uniform Load (N/M²) |

| LP-2019 | FS440 | 600x600x35 | ≥ 200 | ≥ 295 | ≥ 5880 | ≥ 9720 |

| LP-2020 | FS662 | 600x600x35 | ≥ 301 | ≥ 445 | ≥ 8850 | ≥ 12500 |

| LP-2021 | FS800 | 600x600x35 | ≥ 363 | ≥ 536 | ≥ 10680 | ≥ 16100 |

| LP-2022 | FS1000 | 600x600x35 | ≥ 453 | ≥ 670 | ≥ 13350 | ≥ 23000 |

| LP-2023 | FS1250 | 600x600x35 | ≥ 567 | ≥ 780 | ≥ 16680 | ≥ 33000 |

| LP-2024 | FS1500 | 600x600x35 | ≥ 680 | ≥ 1005 | ≥ 19980 | ≥ 34500 |

| LP-2019 | FS440 | 500x500x28 | ≥ 200 | ≥ 295 | ≥ 5880 | ≥ 9720 |

| LP-2020 | FS662 | 500x500x28 | ≥ 301 | ≥ 445 | ≥ 8850 | ≥ 12500 |

| LP-2021 | FS800 | 500x500x28 | ≥ 363 | ≥ 536 | ≥ 10680 | ≥ 16100 |

Wood Core Raised Access Floor

This panel provides a strong loading capacity and can be covered with a PVC, HPL or Ceramic tile. The high-density chipboard core is encapsulated with galvanized steel providing a strong structural integrity while also providing minimal sound when walking on the floor.

| Model | Int. | Size (mm) |

Concentrated Load (KG) | Impact Load (N) | Ultimate Load (N) |

Uniform Load (N/M²) |

| LP-3011 | FS440 | 600x600x32 | ≥ 200 | ≥ 295 | ≥ 5880 | ≥ 9720 |

| LP-3012 | FS662 | 600x600x40 | ≥ 301 | ≥ 445 | ≥ 8850 | ≥ 12500 |

| LP-3013 | FS800 | 600x600x40 | ≥ 363 | ≥ 536 | ≥ 10680 | ≥ 16100 |

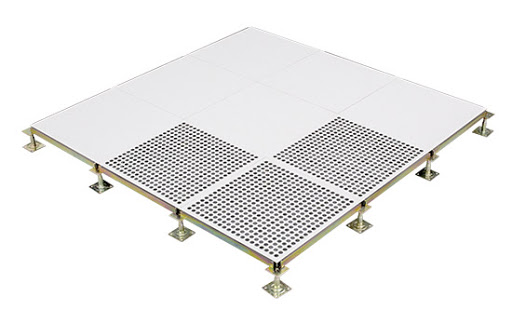

Air Flow Raised Access Floor

This panel is the perfect solution for computer rooms, data centers, monitor control centers, electronic buildings and environments that require air conditioning as well as anti-static flooring.

These can be installed with any steel or wood core panels and have ventilation options from 15%-75%.

Important Notes to Consider

1. Environmental requirements for applicable fields:

Temperature: 10-30°C (5-35°C for Steel Floors)

Relative humidity: RH 30-70%

Temperature change rate: T≤15°C / hour

Vibration: No frequent vibrations

Chemical Environment: No highly corrosive volatile substances

2. Water wash is prohibited for cleaning the surface of the raised floor. A dry mop shall be used to clean it, this prevents the surface of the floor from being desquamated and metal parts becoming rusted and corroded.

3. It is forbidden to use hard or sharp tools to extrude, impact or scratch the cover of the floor and plastic-sprayed layer.

4. A special panel lifting tool must be used for opening or installed raised floors. Do not use any other tool to pry up the panels.

5. In areas with high traffic such as corridors and gateways etc, excessive loads should be avoided.

6. With regard to extended periods of heavy load, auxiliary support will be added to the relevant part of the floor if the weight of one of the machine nearly reaches or is bigger than 1/3 of loading capacity of the floor.

7. Sound may be heard when walking on the floor after laid. This is caused by ground condition, not by the quality of the flooring system.

8. Don’t load excessively heavy items without first checking with our professionals to ensure the floor can handle the weight.

9. Avoid direct sunlight if possible to prevent the cover layer from changing colour and aging sooner than expected.

10. Do not lay gas pipes and water pipes under the floor.

Have a Project in Mind?

Take The First Step Today!

Contact Us

Head Office | 20 Gurnsey Street, Guildford NSW 2161

02 8704 1557

About Access Floors Australia

Access Floors Australia was formed after identifying a gap in the market for reliable and efficient building services, particularly in the raised floor systems space. Completing projects from single room offices through to entire building developments and complex data centres, we’ve done it all and with over 12 years experience, you can trust that Access Floors Australia will provide a custom solution based on your specific needs.

AUSTRALIAN

OWNED

AND OPERATED